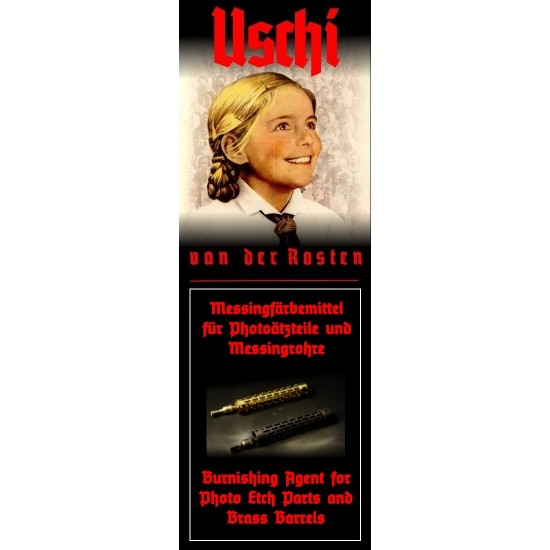

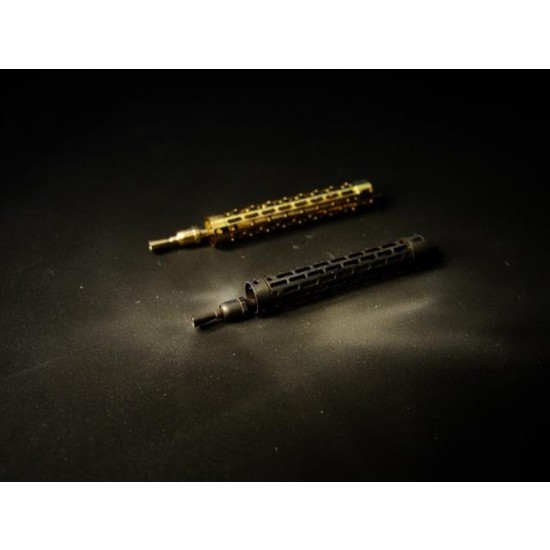

Burnishing Agent for Photo-Etched Parts and Brass Barrels (Natural Gun Metal)

Out Of Stock

Burnishing Agent for Photo-Etched Parts and Brass Barrels (Natural Gun Metal)

This product has been designed to get your brass pieces just look right instantly.

It "blackens" your turned brass barrels and photo etch within about 3-5 minutes. If you soldered your PEs, the Agent will blacken the tin solder as well. Please be advised that this only can be true for the most common solder tins. We cannot provide a 100% guarantee if this also will work with the tin on your workbench since there are various manufactuers using various formula. Just to be honest with you.

Until now, no inoperable soldering tin has been identified.

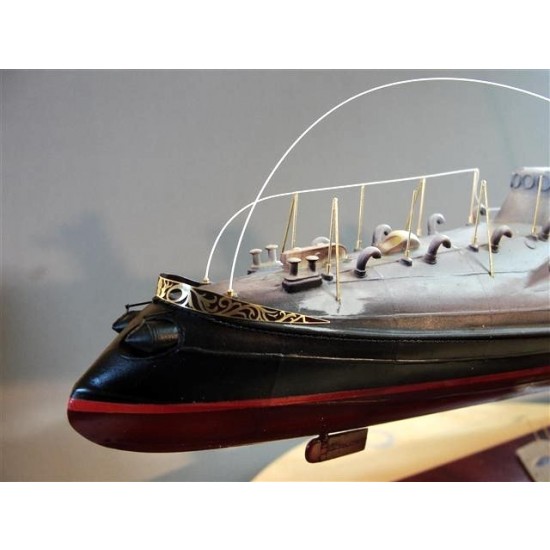

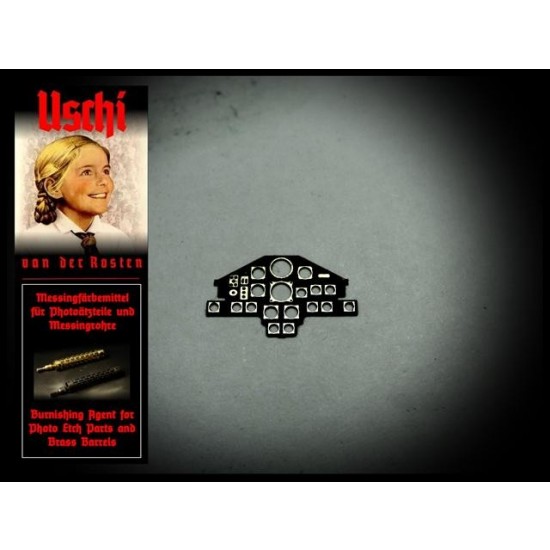

If one has an intrument panel in PE for example. Just put in and let it blacken a bit. We are now about to clean it actually. What we see is a process called "scaling" and that means the all impurities are about to vanish as part of a slow and soft chemical reaction, very similiar to oxydation.

We now take a tissue or paper towel and gently whipe away all undesired oxidation products. Our PE piece now will appear in a very dark brown.

We better dont touch it and use a pair of tweezers in order to make sure having a clean part.

Again we put our PE piece into the liquid and let it react.

Once the desired color has been achieved, take it out, carefully clean it with a tissue and then polish with a polishing fleece of high grid. All raised detail will pop out.

How to deal with the (potencial) super glue-issue:

In case we have to blacken pre-assembeled units which are stuck together with superglue, we might discover some uncovered spots now. This happens sometimes on the joints of the parts.

I just used some black oil color and covered these spots, blending them into the areas where the blackening effect takes place. Its normal and logic that corners are darker than exposed parts of a piece. It looks very natural.

* For more product details please check the manufacturer (Uschivdr)'s website:

http://www.uschivdr.com/products/uvdr-2-brass-burnishing/

It "blackens" your turned brass barrels and photo etch within about 3-5 minutes. If you soldered your PEs, the Agent will blacken the tin solder as well. Please be advised that this only can be true for the most common solder tins. We cannot provide a 100% guarantee if this also will work with the tin on your workbench since there are various manufactuers using various formula. Just to be honest with you.

Until now, no inoperable soldering tin has been identified.

If one has an intrument panel in PE for example. Just put in and let it blacken a bit. We are now about to clean it actually. What we see is a process called "scaling" and that means the all impurities are about to vanish as part of a slow and soft chemical reaction, very similiar to oxydation.

We now take a tissue or paper towel and gently whipe away all undesired oxidation products. Our PE piece now will appear in a very dark brown.

We better dont touch it and use a pair of tweezers in order to make sure having a clean part.

Again we put our PE piece into the liquid and let it react.

Once the desired color has been achieved, take it out, carefully clean it with a tissue and then polish with a polishing fleece of high grid. All raised detail will pop out.

How to deal with the (potencial) super glue-issue:

In case we have to blacken pre-assembeled units which are stuck together with superglue, we might discover some uncovered spots now. This happens sometimes on the joints of the parts.

I just used some black oil color and covered these spots, blending them into the areas where the blackening effect takes place. Its normal and logic that corners are darker than exposed parts of a piece. It looks very natural.

* For more product details please check the manufacturer (Uschivdr)'s website:

http://www.uschivdr.com/products/uvdr-2-brass-burnishing/

| General Info | |

| Scale | Non-Scale |

| Type | Weathering / Effects |

| Subtype | Burnishing Liquid |

- Stock: Out Of Stock

- Reward Points: 12

- SKU: UC 4003

MRP: US$14.73 US$2.5817% OFF

US$12.15

(excl. Tax)

US$6.20

Ex Tax:US$6.20

US$9.93

Ex Tax:US$9.93

US$6.20

Ex Tax:US$6.20

-200x100.png)